Suitable materials and methods for concrete repair

In this article, we discuss the appropriate materials and methods for concrete repair. To buy and know the price of super lubricant, tile adhesive, anti-acid mortar, rebar planting adhesive, concrete restorer, epoxy and antifreeze grout, etc., you can contact Shimi Abadgaran company.

فهرست مطالب

- 1 Suitable materials and methods for concrete repair

- 2 Selection of repair mortar

- 3 Set time and speed

- 4 Surface preparation

- 5 Installation

- 6 Purchase and price of super lubricant, tile adhesive, anti-acid mortar, rebar planting adhesive, concrete restorer, epoxy grout and antifreeze company Shimi Abadgaran

- 7 the address of Central office

- 8 Address of Shahriar factory

Suitable materials and methods for concrete repair

There are many choices in today’s market for concrete repair materials.

Manufacturers make a variety of materials: cement-based, modified acrylic, epoxies, and other chemicals, all of which can be confusing.

There are many choices in today’s market for concrete repair materials.

Manufacturers make a variety of materials: cement-based, modified acrylic, epoxies, and other chemicals, all of which can be confusing.

The first step in choosing repair mortar is to determine the strength of the parent concrete structure. For long-term repair of weak, inadequate, or severely cracked concrete, replacement may be more cost-effective than repair. If you plan to proceed with the repair, you must determine the cause of the concrete damage and the continued use of the concrete.

If the strength and integrity of the original concrete is not compromised. You can easily choose the repair mortar and the execution method for the repair.

When a visual assessment reveals severe discomfort such as extensive cracking in structural elements or any problem that may affect the integrity of the structure and beyond your expertise, it is best to seek professional help.

A professional consultant or engineering firm may be required for an extensive evaluation including testing.

Before engaging further expertise, consider a few more questions. Does the service environment help the problem? Is the area internal or external? Does freezing and thawing occur? What kind of traffic loads is the main concrete subjected to? Is the area exposed to extreme heat or cold, such as near or in an oven or freezer? Will this material come in contact with chemicals such as de-icing salts? Is repair time sensitive? Will this area be used during the repair? Is there a specific time to do the repair? These and other questions will help you choose a repair mortar.

Selection of repair mortar

Product efficiency is an important point. Repair mortars are formulated as trowelable, pourable, pumpable, sprayable, flowable, or self-leveling.

Flowable mortars work well in relatively smooth horizontal applications. Spray mortars are best suited for high volume applications involving vertical and overhead placement.

Troweled or hand packed mortars can be formulated for vertical, horizontal or overhead applications.

Vertical and overhead trowels are usually designed to hang well during placement.

Most troweled horizontal repair mortars contain slightly larger sands for better abrasion resistance. Most molding and pouring mortars are formulated to contain aggregate for larger volume repairs. These are also pumpable for faster placement.

Set time and speed

Adjusting the timing and speed of strength development is also an important factor.

How long should this area be opened to traffic? Repairing a bridge deck on a busy road requires a quick-setting mortar and high-strength initial development, while repairing a residential pavement in most cases does not.

Other important considerations for the physical properties of repair mortars include resistance to freezing and thawing for areas subject to repeated freezing and thawing and coefficient of thermal expansion. For repairs exposed to temperature changes. The material must be similar to the concrete being repaired.

In structural situations, the modulus of elasticity or stiffness of the material affects load transfer. Stiffer materials deform less under a given load than materials with lower modulus.

Structural repairs require that the modulus of elasticity is similar to the concrete substrate. While non-structural repairs can use a lower module.

Compensating for low shrinkage in materials to reduce cracking after placement. It is especially desirable in high volume repair applications.

Bond strength, permeability, water vapor transmission, sulfate resistance, wear resistance, tensile and bending strength may also be factors in the selection of repair mortar.

Surface preparation

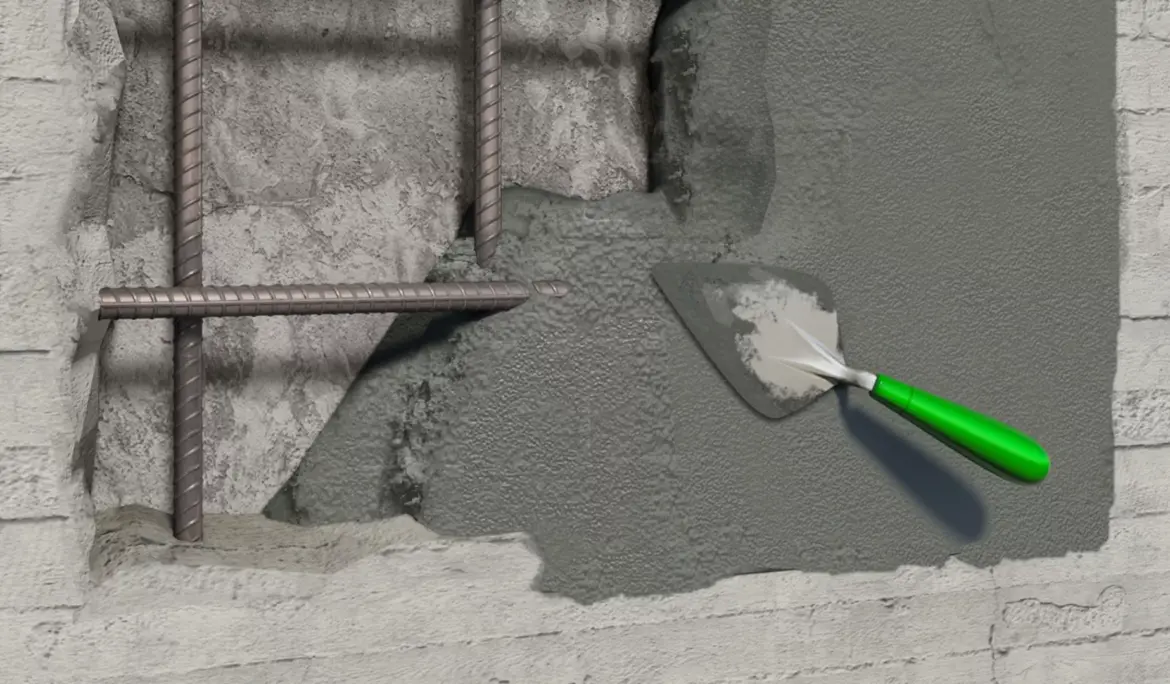

Often, even more than the repair mortar selected, proper surface preparation may be the single key factor in the success of a repair installation. All uneven concrete must be removed.

When preparing an area, simple settings are best. Preferably with square cut corners for load transfer. Avoid inside corners. A uniform depth of the repaired area is also desirable. Avoid feathering, especially on any surface that has traffic.

Cracks in concrete generally indicate movement. Filling a dynamic or mobile crack with rigid repair mortar will only cause the crack to crack. Movement must be stopped or eliminated by a control joint to manage cracking. Cracks can be welded together with an epoxy. However, failure to stop movement or install control joints will also result in the reappearance of cracks.

Installation

Most concrete repair materials require SSD (Surface Saturated Dry) substrate. Before installing the cement base repair mortar, the substrate must be saturated with water. However, to maintain the material-water-cement ratio, make sure to remove the padding water or standing water.

Another key is the placement of the bandage coat. In the saturated area, just before the final placement, place a small amount of the mixed mortar on the area and work it into the area well with a stiff brush.

Do not pour water or excess liquid on this scrub cover. Because it increases the ratio of water to cement and creates a weak connection line in the repair.

While the scrub coat is still damp, install the repair mortar.

Read more: Epoxy rebar planting glue

Purchase and price of super lubricant, tile adhesive, anti-acid mortar, rebar planting adhesive, concrete restorer, epoxy grout and antifreeze company Shimi Abadgaran

With more than two decades in the field of production of chemical products for the construction industry, Abadgaran Chemical Company, in addition to producing more than a hundred types of construction chemical products, has a history of cooperation in implementation and consulting in large national, personal and corporate projects. Shimi Abadgaran Company has a large share in construction chemical products and has more than fifty production forces and laboratories. These are only a part of the extensive cooperation of chemical growers during these years. To buy and know the price of super lubricant, tile adhesive, rebar planting adhesive, anti-acid mortar, rebar planting adhesive, concrete repairer, epoxy and antifreeze grout and polymer mortars, anti-acid mortar, super lubricant and concrete repairer. , epoxy grout, anti-acid mortar, etc. You can contact Shimi Abadgaran company.